What is On-Site Generation (OSG)?

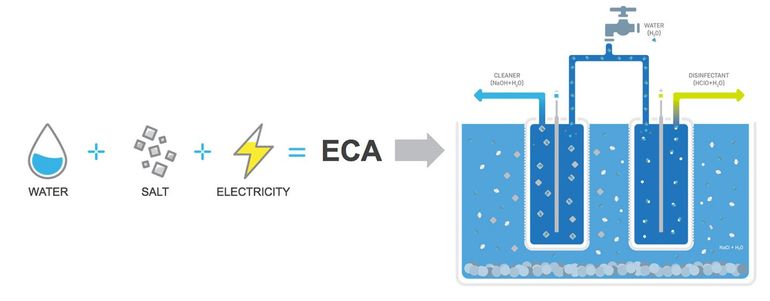

On-site generation or OSG refers to the creation of cleaning solutions through the use of ECA (Electrochemically-Activated) water technology on demand and on site.

The system uses electrochemical activation technology and requires just salt, water, and electricity for operation. Scaling up to meet increased demand for cleaners and disinfectants is easy. You have complete control over the volume of solutions produced. Instead of relying on off-site, conventional chemical manufacturers and distributors, produce as much as needed to clean nearly every surface in your facility – upholstery, counters, work areas, carpets, floors, bathrooms, appliances, linens and more.

Our two solutions, PathoClean® and PathoCide® can replace many of the toxic conventional chemicals being used to clean and disinfect your facility today. Mitigate the risks associated with supply chain disruption.

| PathoSans On-Site Generation | Conventional Cleaning Chemicals | |

|---|---|---|

| AVAILABILITY | Produce on-demand at your premise. | Dependent on supplier delivery. High chance on delays or shortages during infection outbreaks. |

| EFFECTIVENESS | Multi-purpose cleaner, sanitizer and odor control | Strong and effective chemistry for cleaning and sanitation. Each of them have specific and limited usage. |

| Pathoclean: ideal for floor mopping and scubbing, table, food contact tools, walls, exhaust system | ||

| Pathocide: General and food contact sanitizer, hand sanitizer and odor deodorizer. | ||

| COST | Fixed rental cost inclusive salt tablet, maintainance, and break down attend. | 1) Chemical pay by order. 2) PPE and checmial safety handling courses needed. 3) Usage surge during festive or outbreaks season. |

| RISKS | 100% Natural ingredient (water and salt), non-toxic and safe for staff and most surfaces. | Harsh chemical might hazards staff's skin and inhalation system. Incorrect mixing might also degrade surfaces. |

| USES | Two solutions replace up to 70% cleaning and sanitizing solution. | Variable SKU to serve different purpose. |

| MIXING | No dilution and mixing required. PathoSans solutions are always ready to use from the machine. | 1) Hazardous mixing requires careful traning and disposible PPE. 2) Mixing dispenser dilute vary depends on water pressure and timely maintanance. |

| WASTE | Encourage reuse the containers by refill Pathosans solutions. | Used plastic drum often discard and end in landfill. |

| SUSTAINABILITY | Reduce up to 50% on energy and water usage. Creates air pollution from manufacturing and transport. | Prodction of chemical, packaging and transportation create carbon footprint. |

| ORDERING | Eliminates ongoing order, produce yourself 24/7. | Requires regular huge storage place, motinoring, manual ordering, delay in delivery, price surge and credit limit issue (late payment or limit exceeded) |

| ARTIFICIAL ADDITIVE | Free from fragrances, dyes, foaming agent and other additives. | Products vary, mostly have fragrances, foam and dyes to make the product thicker and good smell, which can be toxic or irritate to staff . |